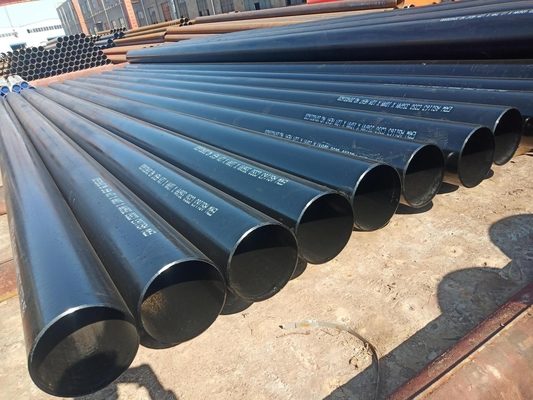

Seamless STEEL PIPE ERW STEEL PIPE

$460.00

ERW steel pipes are manufactured by low-frequency or high-frequency resistance “resistance”. They are round pipes welded from steel plates with longitudinal welds. It is used to transport oil, natural gas and other vapor-liquid objects, and can meet various requirements of high and low pressure. At present, it occupies a pivotal position in the field of transportation pipes in the world.

- High dimensional accuracy. ERW steel pipe diameter and wall thickness than the seamless steel pipe deviation is much smaller, because of the high dimensional accuracy of strip rolling and pipe material control.

- Good mechanical properties. As the ERW steel pipe with easy control of rolling, with the welding technology and on-line heat treatment technology, the performance of the weld can be controlled, so straight seam welded steel pipe elongation than seamless steel pipe 8% -10% higher, which Is because the straight seam electric-welded pipe carbon content of less than 12% lower than the seamless tube.

- ERW steel pipe with high concentricity, uniform wall thicknessAfter heat treatment, the microstructure is uniform and has a strong ability to collapse.

- As the extension of the steel is good, the flattening test of the straight seam steel pipe is better than the seamless test.

- The impact toughness of ERW steel pipe is higher than that of seamless steel pipe.

Specifications

| Material | A53 Gr.B,A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65X70 |

| Standard | API 5L,ASTM A106 Gr.B,ASTM A53 Gr.B,ASTM A179/A192,ASTM A513,ASTM A671,ASTM A672,BS EN 10217,BS EN10296,BS EN 39,BS6323,DIN EN10217 |

| Certificates | API 5L,ISO9001,SGS,BV,CCIC |

| Outer Diameter | 15mm-1200mm |

| Wall Thickness | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS |

| Length | 1m,4m,6m,8m,12m according to buyer’s request |

| Surface Treatment | black paint,varnish,oil,galvanized,anti-corrosion coated |

| Marking | Standard marking,or according to your request.Marking Method:Spray white paint |

| End Treatment | Plain End/Bevelled End/Grooved End/Threaded End With Plastic Caps |

| Technique | Hot Rolled or Cold Rolled ERW |

| Package | Loose package;Packaged in bundles(2Ton Max);bundled pipes with slings at the both end for easy loading and discharging;wooden cases;waterproof woven bag |

| Test | Chemical Component Analysis,Mechanical Properties,Technical Properties,Exterior Size Inspection,hydraulic testing,X-ray Test |

| Application | Liquid delivery,structure pipe,construction,petroleum cracking,oil pipe,gas pipe |

During ERW pipe welding, heat is generated when current flows through the contact surface of the welding area. It heats the two edges of the steel to the point where one edge can form a bond. At the same time, under the action of the combined pressure, the edges of the tube blank melt and squeeze together.

Reviews

There are no reviews yet.