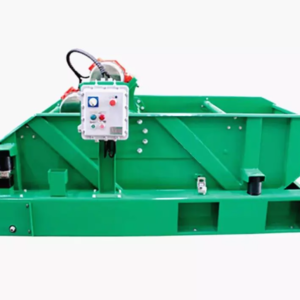

Oilfield High Speed Centrifuge

The oilfield high speed centrifuge is one of the important equipment for solid-liquid separation in the solids control equipment. It is generally installed at the last stage of the solids control system to remove harmful fine solid particles such as cuttings in the mud to ensure rapid drill safely, or recycle valuable heavy materials such as barite, saving mud costs.

For processing non-weighted drilling fluid, it can remove harmful solid phases above 2μm; processing weighted drilling fluid can remove excess colloids in the drilling fluid, control the viscosity of the drilling fluid, and recover barite; treat the cyclone underflow and recover the liquid phase, Reduce the waste of fresh water or oil; In addition, the LW series drilling fluid centrifuge is also an ideal equipment for processing waste drilling fluid in a mud non-landing system to prevent environmental pollution

There are currently 4 series of drilling fluid centrifuges manufactured by Xi'an HL, namely LW355 series, LW450 series, LW500 series and LW630 series centrifuges. Each series is divided into two types: medium and low speed and high speed. These four series of centrifuges can basically meet all requirements for oil and gas field exploration drilling fluid processing.

Parameters

| Parameters | Unit | LW-500X1000-N (Power frequency) | LW500×1000BP-N High speed frequency conversion

|

||||||||||||

| N1 | N2 | N3 | |||||||||||||

| Internal diameter of bowl straight section | mm | 500 | |||||||||||||

| Service length of bowl | mm | 1000 | |||||||||||||

| Rotational speed of bowl (max.) | r/min | 3000(Fresh water) | |||||||||||||

| Service speed of bowl | r/min | 2300 | 2500 | 2700 | <=3000 | ||||||||||

| Separation factor

|

1537 | 1817 | 2119 | <=2518 | |||||||||||

| Pusher differential speed | r/min | 10~50 | <=60 | ||||||||||||

| Rotation direction of bowl and differential pulley

|

It is clockwise when viewed from the small end of the drum

|

||||||||||||||

| Spiral blade characteristics

|

Double head, left hand

|

||||||||||||||

| Max capacity | m3/h | 30 | 40 | 50~60 | |||||||||||

| Main motor | Model | YB225S-4 | |||||||||||||

| Rated power | kW | 37 | |||||||||||||

| Rated rotational speed | r/min | 1470 | 1480 | 1470 | |||||||||||

| Back motor | Model | YB160M-6 | |||||||||||||

| Rated power | kW | 7.5 | |||||||||||||

| Rated rotational speed | r/min | 970 | |||||||||||||

| Single screw feed pump | Vertical sand pump LSB50-7.5 | ||||||||||||||

| Dimensions | Length | mm | 2660 | ||||||||||||

| Width | 1670 | ||||||||||||||

| Height | 1760

|

||||||||||||||

| Weight( With feed pump) |

kg | 3400 | 3500 | 4000 | |||||||||||

Structure

Installation

1.The host installation should be placed horizontally and smoothly, no need to fix with anchor screws

2. The slag outlet is designed with a channel for direct gravity discharge; the liquid outlet is also equipped with a detachable 360°rotating pipeline, which can be determined according to the needs of users

3. There should be enough working space around the equipment for easy operation.

4. The operating surface of the centrifuge is equipped with a clean water valve inlet pipe and a control valve for cleaning the bowl and the slag outlet dilution device. The clean water pipeline should be installed during installation.

5. Adjust the fixing screw of the main motor to make the belt tight.

6.Turn on the power and start the main and auxiliary motors respectively, so that the direction of

rotation is consistent with the marked direction on the main bearing housing.

7. After running empty for 2 hours, check whether the connecting parts of the centrifuge are loose,

whether the belt tension is proper, whether the differentials, fluid couplings are leaking, whether

the bearings are hot, etc., and immediately adjust before running.

8. Then the depth of the liquid pool is reduced to improve the dryness of the slag discharge after

treatment (the slag conveying power increases and the treatment capacity is correspondingly

reduced); if the overflow radius is reduced, the depth of the liquid pool increases, which will reduce

the slag discharge after treatment The dryness (the slag conveying power decreases and the

processing capacity increases accordingly).

Reviews

There are no reviews yet.