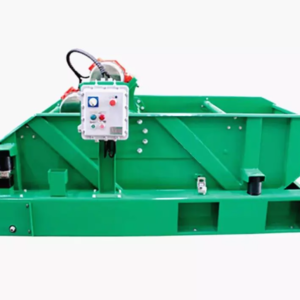

Oilfield Decanting Centrifuge

The oilfield decanting centrifuge is one of the important pieces of equipment for solid-liquid separation in solids control equipment. It is usually installed at the last stage of the solids control system to remove harmful fine solid particles such as cuttings in the mud, to ensure fast and safe drilling, or to recover valuable heavy materials such as barite, and save mud costs

Features

1). Large processing capacity

2). The core components are made of duplex stainless steel, wear-resistant and corrosion-resistant

3). Overload protection, safe operation

4). Flow control, continuous discharge

5). Explosion-proof design to adapt to harsh environments

Features

This series of oilfield decanting centrifuges use a hydraulic coupling to drive the drum, adjust the spiral speed through a planetary gear differential to achieve low-speed and high-torque power transmission, and are equipped with mechanical and electrical double overload protection devices. The inner spirals are all made of cemented carbide inserts and are designed with a special suspension structure. The blades are highly resistant to wear and the whole machine has a large processing capacity.

Application

There are two main reasons for using centrifuges in the drilling fluid maintenance process:

(1) Selective separation and aggravation of colloidal particles and ultrafine particles in the drilling fluid. (2) Remove fine particles in non-aggravated drilling fluid

Pictures

Delivery

1 set oilfield decanting centrifuge delivered to oilfield

Reviews

There are no reviews yet.